|

|

|

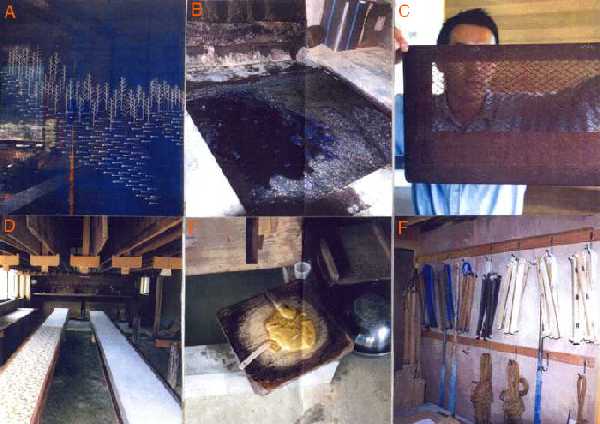

Many steps are involved in the process: the paste resist (made of rice starch) is applied to the cloth using stencils which are repeatedly moved along the length of the cloth. For a kimono, approximately 13 yards of 23-inch-wide cloth is required. The cloth is stretched over boards which are half the total length, with the completed section rolled up to spread out the remaining half. The cloth is then died in indigo vats, soaked in water overnight, and washed out, removing the resist paste. Only the finely detailed patterns remain in the delicate indigo color.

A) A completed design on indigo-dyed cloth

B) Indigo dye ready to be used, in vats set into the concrete floor to maintain temperature

C) Nobuo Matsubara holding up a stencil

D) The workshop with cloth stretched over boards set on tables

E) The rice paste resist

F) Tools used in the process